What are the Benefits of ERP Software for the Manufacturing Industry?

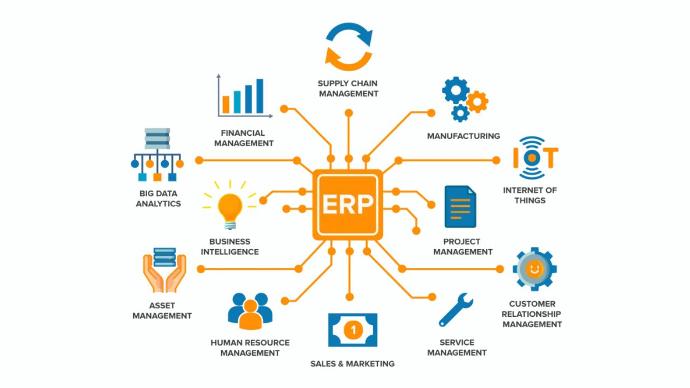

ERP (Enterprise Resource Planning) software is an electronic system that helps enterprises create, manage and automate their business operations.

It automates the processes and increases data reliability, thereby giving a boost to the manufacturing industry. The manufacturing industry is one of the most capital-intensive industries. Hence, investing in it requires a holistic approach.

However, with the help of ERP software for the manufacturing industry, it becomes much easier to manage capital expenditures in the long run and cut down on costs.

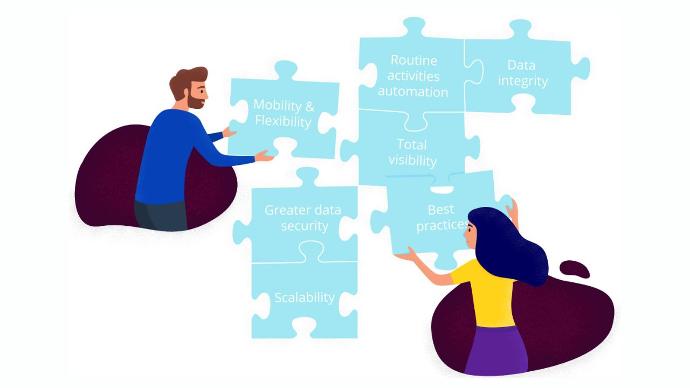

We have compiled Six benefits of using ERP software for the manufacturing industry to increase ROI, reduce the cost of operations, and improve productivity.

Increased Accuracy and Reliability of Data:

With ERP software for the manufacturing industry, you get accurate information about your operations. The data that you collect with the help of ERP software is reliable, as it is an amalgamation of various data sources. You get complete visibility of all your assets, liabilities, and operations with the help of this software.

All the data that you collect is linked with your accounting system and other systems of your organization. This data is highly reliable and accurate. Hence, you can use it to make decisions and take actions with a high degree of accuracy and reliability.

You can track your inventory and manage production. You can monitor and control your production with the help of ERP software. Make sure that your inventory quantity is adequate and that no product goes out of stock. Manage your sales and marketing activities to get maximum revenue from the sales of your products.

It also lets you manage your finance and HR functions. You get complete visibility of all your operations and assets, which makes it easy to control and manage them.

Increased Process Visibility and Control with the ERP System:

Get complete visibility of your operations, while using open ERP software for the manufacturing industry. View and track the progress of your operations through graphs, charts, and other dashboards.

Easily pinpoint any area of your business and make necessary changes as and when needed. With this software, you can track and analyze your operations in detail.

View the status of various assets, track the performance of employees, and take corrective actions, the financial status of your business, and forecast the revenue and expenses in real-time.

In case, you have any issues, take it up with the help of ERP software(Enterprise resource planning system). Conduct regular audits of your operations and assets.

Reduced Operational Costs with the Help of ERP Software

As a business owner, your focus is on increasing revenue, innovating products, and driving competition for survival in an intense market.

The manufacturing industry is about making things and it is not a low-margin, low-volume business. The cost of production is very high in this business as any reduction in production or increase in production from one week to another results in an increase in cost.

However, with ERP integration for the manufacturing industry, you can track the quantity of production, capacity utilization, and inventory of your business.

It makes sure that the production capacity utilization is above 90%. The raw material and other inputs used are recorded. View the operational cost of your business and take corrective actions. In case, you have any issues, you can take them up with the help of Help Desk CRM Software.

Link All the Departments of the Manufacturing Industry:

To increase the reach and application of ERP software, it gathers data related to various departments of the manufacturing industry.

At present, the manufacturing industry has various departments such as finance, sales and marketing, logistics, and so on. All these departments need data related to their operations and they can't share data with each other.

However, with ERP platform software for the manufacturing industry, you can integrate these departments and create a single view.

Share data related to the same business processes like order fulfillment, supply chain management, and order management. This will help in achieving cross-departmental goals and also increase the efficiency of operations of all departments.

Streamline the Supply Chain and Order Fulfillment Process:

While implementing the best ERP software for the manufacturing industry, you can track the status of your inventory and accordingly plan your dispatch, production as well as purchase.

Set various automation routes where you can set automated planning of the production of your finished goods based on the orders you receive as well as for the minimum stock level you have set on each product.

Based on the planned production orders, Manufacturing ERP Software will also forecast the need for each Raw material, and if any material is not available or goes below safety stock, it will auto-create the procurement and intimate purchase department to buy this material.

It will automate production planning and purchase planning, which will reduce many hours of manual effort and increase the productivity of your business, avoid production failure because of stock availability issues.

It will definitely increase your production with the available resources like, employees and machinery you have. It will reduce the production costing which will ultimately result in an increase in profit with ease.

Empower the Workforce with Automation Skills:

The manufacturing industry is one of the most invested sectors of the economy. Hence, the employees in this sector require specific skills.

As an owner of this business, you need to make sure that you train your employees to the right level and keep them engaged in their work. However, with this software, you can automate the skills of your employees.

The workforce of the manufacturing industry requires specific skill sets like inventory management, SCM ( supply chain management ), sales and marketing, and others.

In the skills recognition module of the best ERP software, you can identify the skills of your employees, assign them to their respective job roles, measure the performance and give them regular feedback.